Mitigate Clinical Risk in Cell Therapy Development with Early Adoption of a GMP-Compliant Process

Cell & Gene Tech Expo: GMP & Regulatory Compliance

Virtual session

April 10, 2025

Sean Menarguez, senior director of business development at MaxCyte®, discusses the benefits of early adoption of GMP-compliant processes

In this session from the Cell & Gene Tech Expo, Sean Menarguez presents Mitigate Clinical Risk in Your Cell Therapy Development with a GMP-Compliant Process from the Get-Go. We were pleased to participate in this important event focused on advancing quality and safety in cell therapy development.

Key topics covered in this session

- How early adoption of GMP-compliant processes can reduce downstream risks: MaxCyte's platform has a regulatory support structure to mitigate risks in scaling, including an FDA master file as well as global technical files across Europe and Asia.

- A collaborative approach to accelerating development timelines: To ease the tech transfer process, our field application scientists are on the ground training research teams and CDMOs around the world.

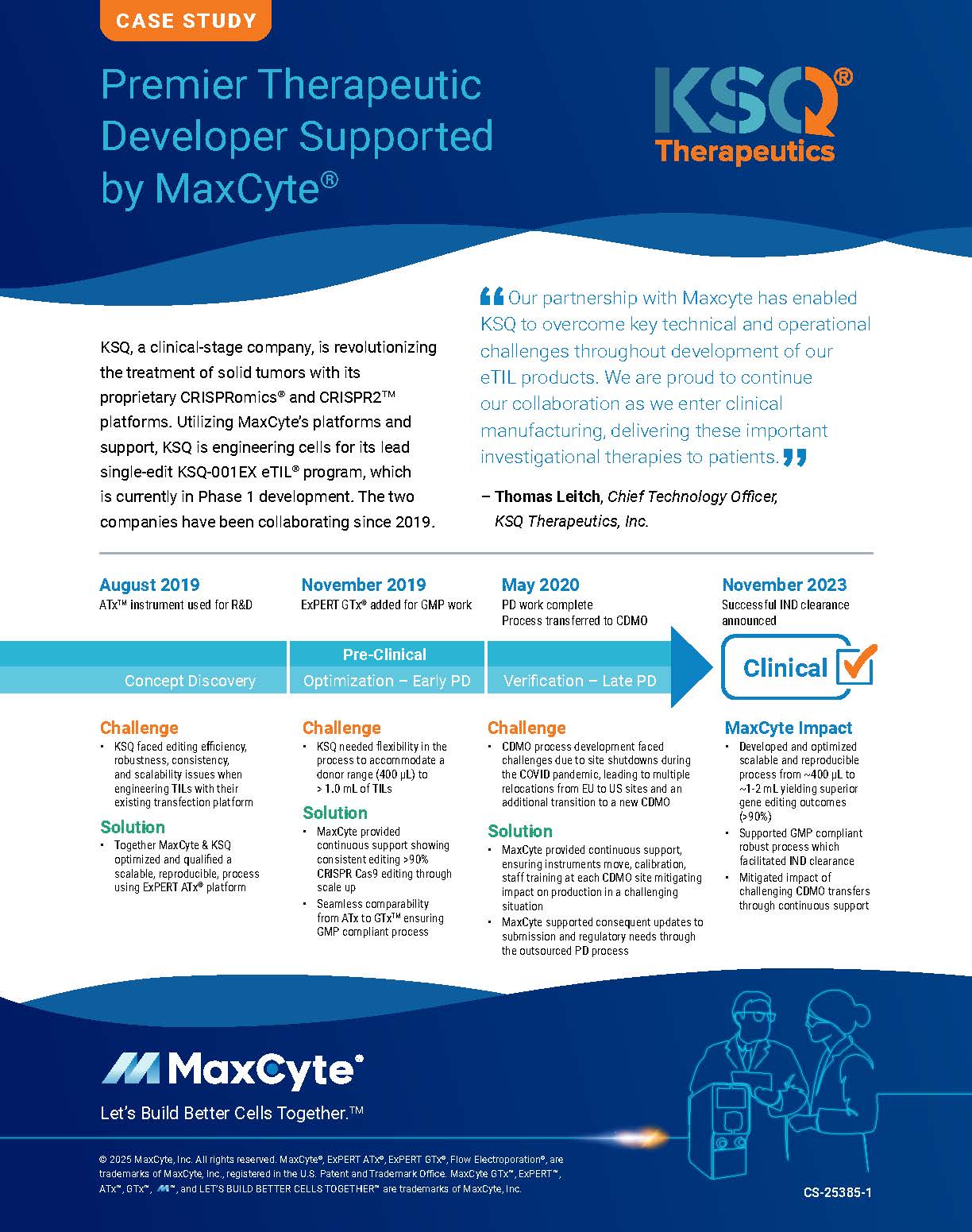

- A case study demonstrating success with support from MaxCyte: KSQ Therapeutics® develops cell therapy for solid tumors using our electroporation platform. This case study emphasizes the importance of early collaboration to efficiently translate a research process into a clinical setting.

Watch more on mitigating clinical risk in cell therapy development:

Case study presented

Collaboration with therapeutic developer KSQ: KSQ is a clinical-stage company that treats solid tumors. In a partnership that began at the research scale, MaxCyte helped KSQ optimize outcomes for their cell engineering early on to secure high transfection efficiency and viability that could easily be scaled to manufacturing. MaxCyte also provided support throughout KSQ's tech transfer to their CDMO. Now the program is in phase 1 development.

Presenter

Have more questions?

Send your question to one of our cell engineering experts.

Transcript

Perry Rearick: Our first presenter is from MaxCyte. He is Sean Menarguez, senior director of global business development. Sean's going to help us discover how to mitigate clinical risk in your cell therapy development with a GMP-compliant process from the very beginning, from the get-go. Welcome, Sean.

Sean Menarguez: Thank you Perry, and thanks everyone for the time and really appreciate the Cell and Gene Expo to be able to have MaxCyte participate today. There's just a quick poll question from the team here at MaxCyte as we get into today's discussion, so really appreciate any responses that you can provide.

And as Perry mentioned today, and Perry, completely appreciate your comments on the uncertainty in these times; these few minutes that we have today are going to discuss how the ecosystem within cell and gene therapy can really collaborate not only from the therapeutic developer side, but also the services and products, and how we can all collaborate within the ecosystem to push more therapies into the clinic to treat patients.

And as you all know well, there's been challenges. MaxCyte works with a variety of cell and gene therapeutic developers, especially in the clinical stages, of the challenges that the industry face, especially with this modality, the high development costs that go into bringing these therapies into the clinic. One portion of that is the different processes of scaling from research into process development into clinical manufacturing, and being able to streamline those processes to be able to get a clinical manufacturing solution that's ready to treat patients. Of course, the regulatory complexities that go into an IND filing, regulatory framework within the clinical trial, and how to mitigate that risk from a manufacturing process standpoint is really to have a clinical manufacturing process from the get-go. As you have line of sight of process development to know that solution is going to scale not only to your phase 1 clinical trial but into your registrational and, ultimately, commercial approval.

And with scalability issues, research work and academic processes may work with lower cell volumes or lower scale [and need to] translate that into process development, but also tech transfer into the cleanroom and make sure the consistency that therapeutic developers are seeing in the process development lab is translating into the clean manufacturing suite. And as you expand the clean manufacturing suites to different sites, even geographic expansion, US and Europe, Asia Pacific, etc., how that consistency yields. Is a run done in Chicago consistent with a run done in London? And of course, speed to market, to be able to accelerate that pathway that will be able to maximize the yields for revenue potential as these therapies come into commercial.

We’ll take a moment today to discuss how MaxCyte takes approach as a platform. MaxCyte is a cell engineering platform where we work with therapeutic developers and their cargo, whether it be a gene editing reagent, such as a CRISPR Cas9, into their specific cell that they're working with, T cells, for example.

The way MaxCyte collaborates is not only from the best-in-class technology to be able to yield those high transfection efficiencies of cargo and viability, but also the cell health and loss of your cell therapeutic product to be able to maximize the therapeutic benefit. We take a collaborative approach of optimizing these protocols that are going to be best for workflows, whether you're working in T cells, NK cells, TILs, macrophages, stem cells and the variety of cargoes that you're working in.

We really take a service type of approach. We understand how difficult it is to translate from an academic research process into a clinical manufacturing process, and translating our know-how and expertise into the customer lab, being able to scale up within that cell engineering step, whether it be optimizing gene editing, reagent concentration, to be able to optimize the yields, different protocol development to maximize the outcomes, whether it be physical conductivity from a closed system from a regulatory set. Working connectivity up and downstream of the platform—and not only in a physical sense, in an information sense as well. As we're looking to scale these therapies from an information connectivity and different electronic batch records to be able to understand how the process is performing. And how can platforms really provide the regulatory and compliance support aspect?

MaxCyte does have an FDA master file that’s [been] in place since 2002. We've been involved in over 70 clinical trials to date across cell and gene therapies. Having the regulatory framework, given that the cell engineering, the gene manipulation step, is such a critical step in the process, how can we mitigate that risk from a platform standpoint with the regulatory agencies? And we have a framework here in the US with the FDA via the master file and have global technical files across Europe and Asia as well.

Today I’m going to take some time to go through a case study of how MaxCyte collaborates with therapeutic developers and how that ecosystem can push these therapies forward into the clinic. KSQ Therapeutics® is a partner of MaxCyte. Again, we take a collaborative approach where we partner with therapeutic companies on their cell engineering process. We’ll discuss their KSQ-001EX product, which is a CRISPR Cas within their engineered TILs program.

And just as background here on this high-level case study: we started working with KSQ Therapeutics when they were more at the research scale and they wanted to optimize their outcomes in that research setting for their engineering—and not only to be able to have high transfection efficiency and viability for their therapeutic product, but also create scale. So we worked with KSQ with our ATx™ platform, which is our research-scale platform, to be able to optimize and protocol-select that would be the best protocol for their TILs program.

And then from there, as you optimize the research process, having that be able to translate into a clinical process, which is in that process development stage, where we have the GTx™ platform, which is our flagship GMP platform to be able to not only scale up from, maybe, a cartridge-based static electroporation that may be in smaller scale, but to scale up to a flow aspect where you can have connectivity up and downstream in a GMP-compliant fashion.

It's not only the performance of the instrument itself, it's also the consistency across a variety of donors, across a variety of patient cells, to be able to achieve those optimal outcomes—and optimizing not only in the process development step [but] translating that into the tech transfer, into the cleanroom manufacturing, where a lot of therapeutic developers in our space will work with CDMO organizations to manufacture their clinical products.

And that tech transfer and ease of tech transfer is critical. MaxCyte has been involved in over 40 tech transfers to date across eight countries, and it's really important to be able to collaborate, especially on something as critical as the cell engineering step, to make sure the work that's being done in the process development lab nears the work that's being done in the cleanroom manufacturing suite. MaxCyte collaborates and works with therapeutic developers and the CDMO training on the cell engineering process to make sure that that tech transfer goes smoothly.

And happy to report, it's really a four-year journey that you see here on the screen, starting in 2019 to 2023. As KSQ has announced that they received IND clearance, they're able to create a GMP manufacturing process from the get-go prior to clinical manufacturing. And now they're currently dosing patients for the phase 1 trial for solid tumors. Which is really critical of how the collaboration of the ecosystem, not just the therapeutic developer, but as we all can move from a products and services base, really drive these therapies forward to reach more and more patients.

Here is just a quick quote from the chief technology officer at KSQ, which really highlights the importance of collaboration, how we can all work together to be able to optimize these processes, create speed in the clinic, allow companies to minimize the cash burn that goes into developing these therapies of research and process developments, and mitigating that clinical risk aspect, really having a clinical ready process from the get-go and always having that scale in mind. Not just scale for a phase 1, but scale in doses for a phase 2, phase 3 and ultimate commercial manufacturing. [How] critical [it] is always to have that end goal in mind without trying to modify or translate a research process into a clinical setting.

[I] really appreciate the time to discuss MaxCyte and how we collaborate with therapeutic developers. Happy to answer any questions that anyone has on our approach.

Perry Rearback: Thanks, Sean. Really great case study. I don't think I'm going too far out on a limb that so many drug sponsors are in that stage of development, I really like the fact that you illuminated that and what you can do. So with that in mind, a few questions. Can you talk a little bit more about process optimization? And what you do during the cell engineering process?

Sean Menarguez: Absolutely, Perry. And you're spot on as well. A large bottleneck for the industry is pushing these therapies over that are in the research or preclinical stage and ultimately getting them ready to dose patients in the clinic. And where MaxCyte really is, given that cell engineering step where you're manipulating the cells to induce the therapeutic effect, that process optimization may go from a biology standpoint of optimizing the different concentration of reagents, how you handle the cells prior to the transfection or cell engineering app.

We take great pride in the consistency of our platform, but as we work with customers, a lot of the times, in order to define the output, you have to define the inputs. And working with kind of the upstream aspect of the cell electroporation, and whether it be not only from a cell biology, but from a connectivity standpoint and having a closed system that you're able to have through our Flow Electroporation® processing assemblies as we call, which are consumables that can connect up and downstream. We have a field application scientist team that goes on site into the customer's lab to be able to collaborate with them on optimizing those processes to make sure they're ready for clinical manufacturing. So hopefully that gives you a little bit background of how we work.

Perry Rearback: Yeah. Very good. Excellent. A question about cell engineering workflow. How do you support that specifically for the clinical manufacturing?

Sean Menarguez: One of the things, as we work with therapeutic developers in the process development lab, is you create a scalable process, but how is that transferred into a cleanroom manufacturing suite and translated into the clinical setting?

We do work with our field application sciences team that is global. So if you are a company that's based in Boston, for example, and you're using a CDMO in Texas, we have field application scientists that are located across the globe that, for example, that field application scientists in Texas can go into that CDMO and be able to work and train and optimize their process.

So the CDMO individuals are trained on a process that was being worked on from a process development standpoint, and that's really critical, to be able to translate those results and outcomes that therapeutic developers see in the process development lab into the cleanroom manufacturing suite.

And it’s also the regulatory and quality aspect of the platform. As you look to submit your IMDs, you know, choosing a clinically validated platform that has the regulatory support framework to be able to mitigate that risk for the clinical manufacturing piece. And again, MaxCyte has an FDA master file that the regulatory agencies have been comfortable with using for cell and gene therapies for over 70 clinical trials.

Perry Rearback: We have an audience question. Could you talk a little bit about your electroporation capabilities?

Sean Menarguez: Yes, one of the key differentiators for MaxCyte is the scale and flow, as MaxCyte has always been designed as a clinical manufacturing platform. It wasn't originally designed for research and then fit for purpose for clinical. The company was founded on engineering blood cells for therapeutic purposes, and the company was founded 25 years ago. So we've been at this for quite some time. And it’s not only with the Flow Electroporation® to be able to scale up from a volume standpoint.

Our CL-2, which is our Flow Electroporation® highest-volume PA [processing assembly], can go up to a hundred milliliters of cells, able to have a close fashion with also consistent results. And also it’s not only the actual platform itself, it's the software that's included with it, and optimized protocols. We have an applications lab here in Rockville, Maryland, where we mirror customer workflow and fine-tune those optimization protocols, um, of the electroporation parameters that are going to make the most consistent viable outcomes.

Perry Rearback: Okay, thanks. And then you mentioned your field application team that's out there. Can you talk a little bit about any support that you provide for regulatory and quality?

Sean Menarguez: Our platforms are all ISO-certified. They're manufactured here in Rockville, Maryland. The reason I bring that up, from an in-house manufacturing standpoint, it allows us to uphold those regulatory quality standards as our instruments and processing assemblies are manufactured in-house. From a supply chain aspect as well, happy to report the company has never had a back order to date. We take great pride in that operational efficiency and understand how critical these materials are as you’re dosing patients. From a regulatory support aspect from a field application scientist is designing those clinical processes that are GMP-compliant, that are ready for clinical manufacturing and having that cell engineering process being supported by our FDA master file and respective technical files off the globe that sponsors can append to their IND and letter of authorization for access to our files to be able to have the regulatory support documentation, given that cell engineering's such a critical step.

Perry Rearback: Well, great presentation, Sean. Some really interesting capabilities that you have. Sean Menargue from MaxCyte, thank you for being with us today.

Sean Menarguez: Thank you, Perry. Thanks everyone for the time. Really appreciate it.