Efficient, Scalable Manufacturing of Virus-like Particles for the Delivery of Gene Editor Ribonucleoproteins Using a cGMP-compliant Electroporation Platform

European Society of Gene and Cell Therapy (ESGCT) Conference

Rome, Italy

October 24, 2024

Our MaxCyte scientist, Isabel Daher, presents her poster from the 2024 European Society of Gene and Cell Therapy annual meeting

Abstract

Genome editing tools such as CRISPR-Cas9 nucleases, base editors, and prime editors hold tremendous promise for treating human diseases by being able to specifically modify a targeted region of the DNA genome. However, there are limited in vivo delivery options that are safe, efficient, and transient. Moreover, viral vectors such as AAV are hampered by limited cargo size capacity. Virus-like particles (VLPs) offer a solution to these problems. VLPs are derived from retroviral structural proteins, which can be engineered to specifically package a cargo of interest. They are safer than traditional viral vectors because they lack a viral genome but can utilize the traditional virus delivery machinery to target and enter cells. Recently, VLPs have been reported to efficiently package base editors and prime editors for delivery into mice at therapeutically relevant levels. To realize the potential of VLPs for in vivo delivery, alternative methods to scale up their manufacturing will be critical for future clinical applications. Here, we utilized the MaxCyte ExPERT GTx, a GMP-compatible electroporation instrument, to manufacture VLPs— packaged with CRISPR-Cas9 or base editor (BE) ribonucleoproteins (RNPs) for genome editing in target cells — human immortalized HEK293T cells and primary immune cells.

We found that electroporation consistently produced significantly higher yields of functional VLPs compared to a commercially available transfection reagent, with greater than 10-fold improvement in p30 titer when using an optimized electroporation protocol. We also demonstrate effective genome editing at the B2M locus, with both CRISPR-Cas9 and BE RNP-packaged VLPs. Furthermore, the production of VLPs using electroporation exhibited favorable production kinetics compared to other transfection methods, enabling a shorter VLP manufacturing process. Finally, we demonstrated the scalability of VLP production across a 15-fold volume range with minimal reoptimization. In summary, our results show that electroporation is a viable means for consistent, efficient, and scalable manufacturing of VLPs for gene-editing applications and has high promise to address needs for future clinical and commercial VLP manufacturing.

Watch Isabel's poster presentation

View the complete poster that established an optimized process for manufacturing virus-like particles using the MaxCyte's Flow Electroporation technology.

Have more questions?

Send your question to one of our cell engineering experts.

Presenter

Related resources

Poster presentation transcript

Hello, welcome to MaxCyte! My name is Isabel Daher, and I am a research associate here at the Technical Applications lab. We’re excited to present to you our efficient and scalable manufacturing process for the packaging of gene editor RNPs into virus-like particles.

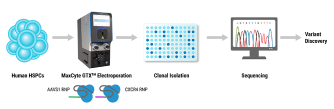

Our workflow first starts by combining the producer cells, either adherent or suspension HEK293 cells, with a four-plasmid mix encoding for both the structural components of the VLPs as well as the cargo. Here, we package CRISPR RNPs for gene editing.

The cells and plasmid master mix are then loaded into one of our static or flow processing assemblies and then inserted into the ExPERT GTx instrument. A pre-loaded and optimized protocol delivers the appropriate energy to enable plasmid delivery before cells are transferred to their respective culture vessel for a short recovery period. Production media is then added, along with a chemical enhancer to improve yield, and VLPs are harvested from the culture supernatant one or two days post-electroporation.

To assess the VLP yield, VLPs are transduced onto either adherent HEK293T or primary human T cells. After three to five days, cells are harvested for genomic DNA extraction followed by sequencing or analyzed via flow cytometry.

When optimizing electroporation, the main two parameters to consider are cargo concentration and electroporation energy. In adherent HEK293 cells, in a dose-responsive manner, increasing DNA concentration helps to improve the potency of the VLPs, reported here as percent indel formation. Additionally, increasing electroporation energy trends with improved potency. And, to further improve the titer, a chemical enhancer was tested in the production media to better improve the yield.

We can now benchmark against a commercially available chemical transfection reagent. On day two, VLPs produced via electroporation exhibit higher editing activity than those produced with chemical transfection. And this is also reflected by the capsid, or p30, titer measured via ELISA.

When comparing the kinetics of VLP production between methods, it is clear that electroporation can enable rapid one-day harvest of highly functional VLPs compared to chemical transfection, where at best, a day-two harvest is required.

This can be explained by not only higher p30 measurements, but also higher and faster incorporation of the CRISPR RNP cargo into VLPs produced via electroporation.

While we now have a validated process in adherent cells, we wanted to test suspension HEK cells for production to accommodate the scale-up required in clinical and commercial manufacturing. Shown here, the same process validated in adherent cells can be seamlessly applied to suspension culture. And the same enhancer can be used to improve yield.

Electroporation can also enable different gene editor RNPs to be packaged. Shown here is an adenine base editor RNP, compared to the wild-type Cas9. Shifting the producer cell culture helps to improve the titer, and therefore, editing capability.

VLPs packaged with RNPs are amenable for in vivo gene editing, and thus must be capable of safe and efficient editing. Adenine base editor-loaded VLPs do not cause cytotoxicity to activated human T cells but can efficiently edit the B2M locus enough to disrupt B2M surface expression more efficiently in VLPs produced with electroporation compared to chemical transfection.

So, we now have an optimized workflow for both adherent and suspension HEK cells, and we’ve also demonstrated functionality. It’s now time to assess the scalability of MaxCyte’s electroporation platform. Here, one billion cells were electroporated in an R-20K processing assembly, and 120 million cells were cultured per condition. When comparing the same producer cell number, electroporation is seamlessly scalable across a 15-fold volume range, and VLPs from both scales outperform those produced with chemical transfection harvested on day one and day two.

Again, a chemical enhancer was added to the production media to help improve functional titer, or editing, as well as the physical, or capsid, titer.

EC50, or effective concentration 50, is a metric used to identify the concentration or dose of a treatment to induce a 50% response; here, is related to indel formation. On day one harvest, electroporation produces VLPs with an approximate 20-fold improvement in potency compared to chemical transfection and a 4.5-fold improvement on day two.

To summarize, we demonstrate MaxCyte’s GMP-compatible electroporation platform is an efficient and scalable method for VLP production, capable of transfecting one billion cells as shown here. We can enable higher VLP-mediated editing activity on a shortened timeline, and in both adherent and suspension HEK cells as you scale up throughout your drug development journey. MaxCyte’s electroporation is a simple, time-saving alternative to chemical transfection for VLP production.

Thank you for attending and please contact us if you are interested or have questions.

Notice: This transcript was generated by a human and may contain errors or inaccuracies. We apologize for any mistakes and appreciate your understanding. If you notice any discrepancies, please feel free to reach out to us for corrections.